Can-Do National Tape is a recognized leader in the converting, fabrication, manufacture, and distribution of a wide variety of pressure-sensitive adhesive tapes as well as foams, fabrics, non-woven materials and other related products. Can-Do’s resources are worldwide. We have reliable relationships with both domestic and international material suppliers.

Our goal is to achieve the most effective and efficient solution to your problem.

About our Services

Although adhesive tape products are usually straight “off the shelf” – it is sometimes necessary to convert these materials to perform a certain function or fit a particular space. Can-Do has developed a state-of-the-art converting facility so we can supply products in the most user-friendly form to accommodate your production needs. Our services range from precision slitting of adhesive tape rolls to virtually any width or length, to die-cutting parts on easy-release liners. Our extensive line of products ensures that Can-Do will have the right material for your application.

Prototype and Product Development

Our ability to service our customers’ development needs, no matter how small, large, specialized, or complex, is unique within the industry. This gives both Can-Do and our customers a competitive edge.

Converting, Fabrication, and Manufacturing Services

Converting a tape product adds functionality, efficiency, and therefore value to your production project. We have invested time and money into developing a premiere production facility, outfitting it with specialized machinery to provide the widest range of fabrication possibilities. Our ability to develop remarkable solutions and produce time-sensitive custom projects for our customers, nation and worldwide, is second to none.

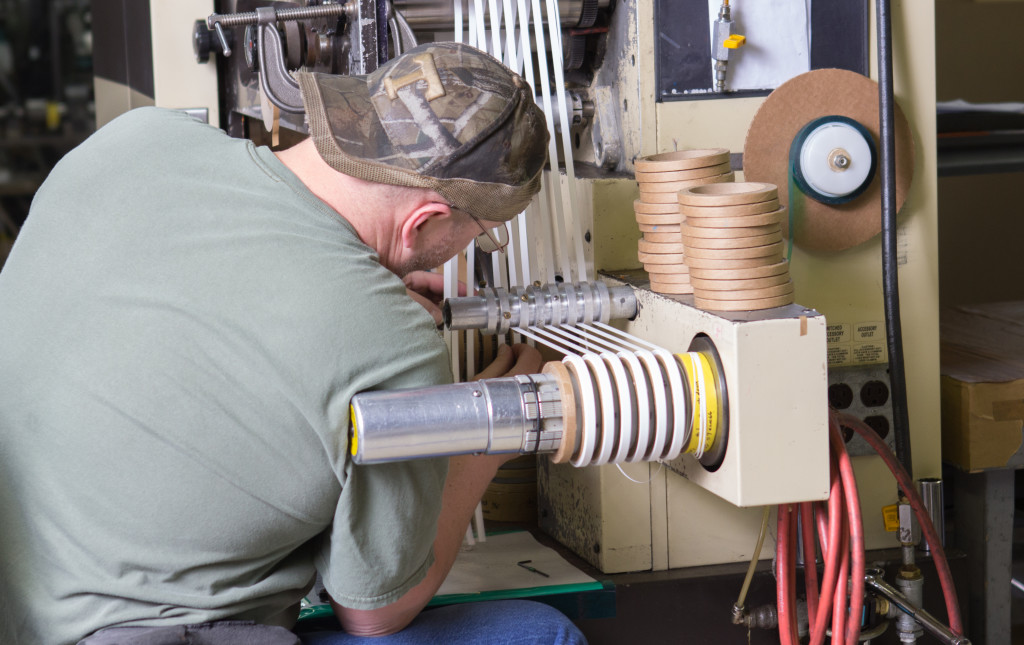

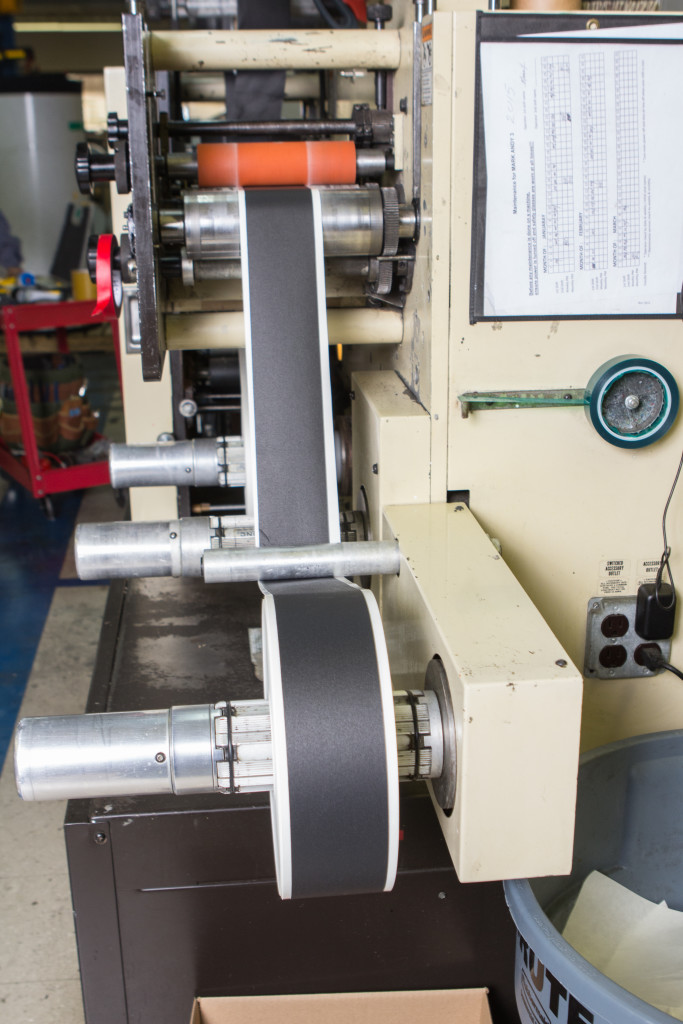

Rewind Slitting

Can-Do employs a variety of methods to slit and rewind flexible materials to achieve the best quality edge. We employ Razor, Score, and Shear slitting technology. Slip differential rewind shafts ensure clean edges and consistent, evenly-wound rolls.

Sheeting

Our streamlined process allows us to economically “sheet” products such as foam, felt, foils, and thin gauge plastics, including hook and loop. Sheeting can be employed in-line with die-cutting processes.

Printing

Utilizing multiple, versatile printing presses allows us to print up to three colors of text or logos on labels and carton sealing tapes, as well as deposit adhesive backing onto other non- adhesive products.

Precision Custom Slitting

Our state-of-the art log slitter gives us the power to precisely slit (slice) rolls of flexible materials into smaller segments. We can slit certain materials to as narrow as 1 mm wide.

Laminating

Can-Do has the ability to laminate rolled or sheet materials up to 64 inches wide. Our heat-assisted laminators can laminate pressure-sensitive adhesive, heat seal films, and web adhesive to numerous substrates, at a range of temperatures. Heat-assisted lamination helps to maintain a consistent and uniform bond throughout the roll.

Die Cutting / Kiss Cutting

Our production facility operates several rotary and steel rule die cutting presses to provide our customers with numerous options. We utilize high speed, tight tolerance rotary tooling, up to 18″ wide for smaller/thinner materials. For thicker, more rigid materials we employ flatbed steel rule dies that can accommodate material up to 60″ x 54″.

Assembly & Kit Packing

We provide pinpoint coordination, customized assembly, and expert performance to deliver total fulfillment solutions.

We Convert Ideas Into Reality

<< Consulting Services >> << Die Cutting >>