Automotive Thermal Bond Tapes

Automotive Differential Heat-Activated and PSA Foam Tapes

Automotive Differential Heat-Activated and PSA Foam Tape is used to attach weatherstrip and/or gasket seals for automotive applications. Being constructed with two different adhesives, the heat-activated adhesive forms an immediate, consistent and durable bond while the pressure-sensitive adhesive is often a high adhesion and bonding strength to many surfaces, including automotive paints and metals. The differential tape provides a good conformability and recommended for automobile and industrial applications.

- Resistance to solvents

- High bonding strength

- Heat resistance for high temperature applications

- Low bonding temperatures

- Precise positioning

Showing all 16 results

-

3/4″ x Custom Length x 3 mil Translucent Seam Tape

-

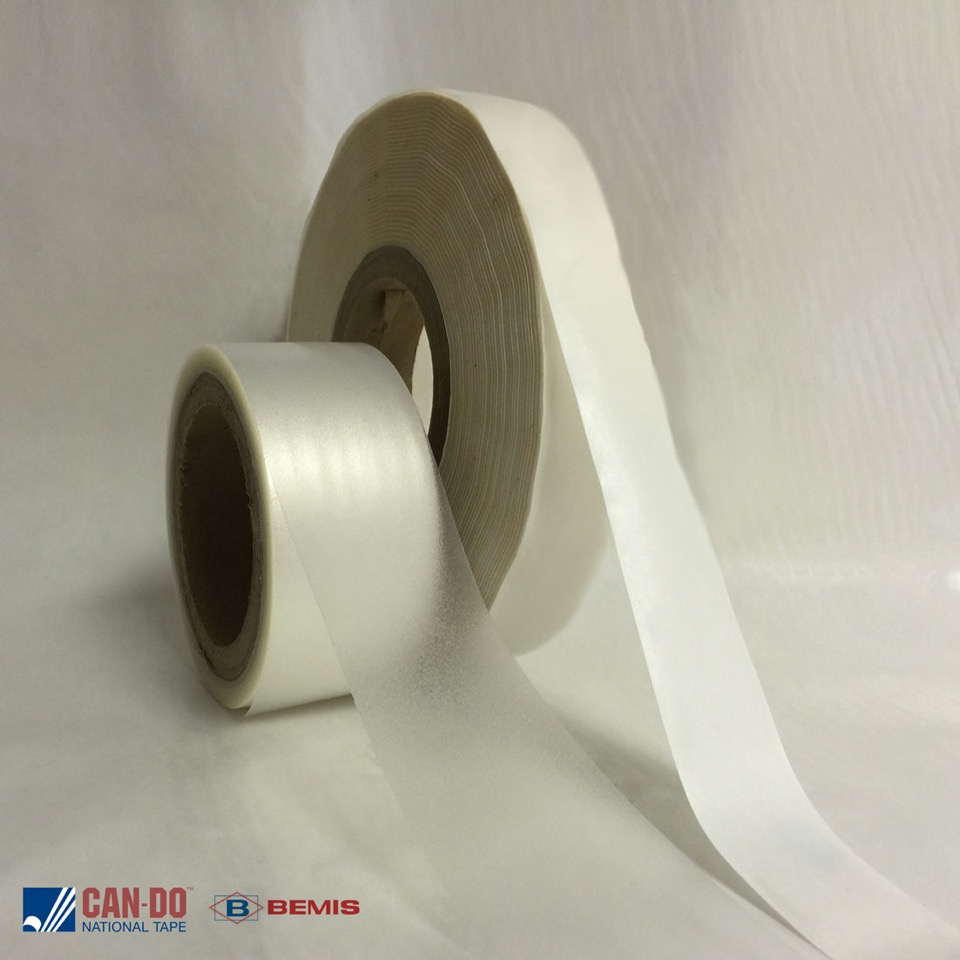

50.75″ x Custom Length x 3 mil Sewfree® Tape | 3 mil

-

7/8″ x Custom Length x 3 mil Translucent Seam Tape

-

7/8″ x Custom Length x 5 mil Translucent Seam Tape

-

7/8″ x Custom Length x 6.5 mil Translucent Seam Tape

-

Custom Converted Clear Sewfree® Tape | 3-7 mil

-

Custom Converted Clear Thermoplastic Polyurethane Sewfree® Tape | 4 mil

-

Custom Converted Clear Thermoplastic Polyurethane Sewfree® Tape | 6 mil

-

Custom Converted Hazy Translucent Sewfree® Tape

Need Help Choosing The Right Adhesive? Not Sure How To Prep The Surface?

Download our free Guide to Better Bonding

Download Now

Download our free Guide to Better Bonding

Download Now

Need Assistance with Troubling Design Issues? See What Tape Can Do!

Download our free Guide to Solving Design Issues with Adhesive Tape

Download Now

Download our free Guide to Solving Design Issues with Adhesive Tape

Download Now