Double Sided Tapes

Double Sided | Double Coated Adhesive Tapes

Double-Sided Tape is any tape that is coated with adhesive on both sides and is designed to stick two surfaces together so that it is not visible in the end product. Double-sided tape is created by applying a thin adhesive to each side of a flexible carrier like coated paper or tissue paper. Being that the tape is located between two substrates, it allows for a cleaner look and a modern designed product. Double-sided tape can be either thin or dimensional. The dimensional tape is thicker and is useful to retail and signage industries where it can be used to allow signs or displays to stand out with a 3-D effect. Many bonding applications are achieved with double-sided adhesive tapes due to the use of varying thickness and bonding properties.

Can-Do National Tape orders and stocks from the best tape manufacturers around and will slit these tapes to custom width, length or size to fit your needs. We provide initial high tack as well as high-temperature resistance. These products are used for laminating applications, splicing purposes as well as for gasketing and sound deadening in automotive and appliance applications. Double-sided tapes with a polyester carrier are available with rubber and acrylic adhesive systems. Can-Do National Tape has over 100 years of experience with double-faced adhesives and has worked with several types of transfer tapes, films, strips, foams, and pads because they are used in so many applications.

Following Categories for Double Sided Tapes:

-

Carpet Tapes (2)

-

Double Sided Cloth Tapes (2)

-

Double Sided Paper Tapes (6)

-

Film Tapes (6)

-

Tissue Tapes (1)

-

Transfer Tapes (60)

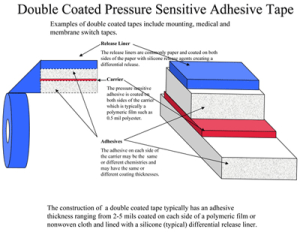

Construction of a double coated tape:

- An Adhesive

- The Carrier

- An Adhesive

- A Silicone

- The Release Liner

- A Silicone

Benefits of using a double coated tape:

- Carrier offers ease of handling and slitting.

- Can serve to reduce over laminating on porous materials.

- Carrier offers ability to use different adhesives on each side (differential adhesive), enhancing application flexibility.

Image Credit: Pressure Sensitive Tape council

Backing or Carrier Material

Double sided tapes vary in terms of carrier material. The carrier or backing material for double sided tapes is a relatively thin, flexible material to which the adhesive is applied. It functions to stabilize the adhesive, improve handling, and provide removability. The carrier also adds thickness to the tape and provides a barrier between adhesive layers. Films are synthetic resin adhesives that sometimes include a carrier fabric.

Release or liner materials for double sided tapes may be differentially-coated for easier peeling. Applying a different release coating on each liner varies the degree of release and allows one liner to peel away from the tape easily. Some release liners are made of paper, film, or silicone-treated sheets. Others are coated with clay or wax. Glassine is a transparent, high-strength liner material that is produced by dampening and supercalendering. Polycoated liners for double coated tapes and transfer tapes are made of paper or kraft paper that is coated with a polymer for easier release.

Double Coated Tape Application

Double sided tapes are compatible with specific types of substrates. These include ceramics and glass, concrete and masonry, composite materials, foam, porous surfaces, leather, metal, paper and paperboard, plastic, rubber and elastomeric materials, textiles and fabric, or wood and wood products.

Custom Converted Double Sided Adhesive Tapes

General Information: Double Sided Tapes have exposed adhesive on each side. So, when you want to stick one surface to another surface, double sided tape is the ideal product. When double sided tape has a carrier in-between each exposed adhesive side, it is commonly referred to as double sided tape because each side of the carrier is sided with an adhesive. When there is no carrier and when the double sided tape is pure adhesive, it is commonly referred to as transfer tape. Transfer tape is merely unsupported adhesive.

Can-Do’s Double Sided Transfer Tapes have a release liner designed for ease of application. The acrylic adhesive film is stabilized, even though the adhesive has no carrier. Transfer Tapes exhibit very high quick stick and holding power, even at elevated temperatures. Adhesive transfer tapes are used for mounting, splicing, and for closure.

- All double sided tape must have a liner in order for it to be “put-up” on a roll; otherwise, it would stick to itself. So, double sided tape is normally constructed with an exposed adhesive a carrier an adhesive and a liner.

- This complicated construction allows a vast array of double sided tape products with varying adhesive systems and different carriers.

- Consequently, selecting the proper double sided tape for your application requires knowledge and expertise. Let a Can-Do National Tape sales consultant assist you with your application needs.

- These tapes exhibit excellent quick tack and high strength for a variety of purposes such as mounting nameplates, and laminating foams, cork or felt products. Double sided tapes also work well on banners and signs.

- Double Sided Tapes with rubber adhesive, when laminated to foam, are used for weather stripping. The double sided polyester tape with the acrylic adhesive is UV resistant and commonly used in outdoor applications.

- There are other carriers, in addition to polyester; and these include paper and tissue carriers. Double sided tape products with these carriers are frequently used on irregular surfaces and for mounting, splicing and laminating paper, cloth and other materials.

- Double Sided Tape with cloth as a carrier is used to hold carpet and other flooring in place for temporary or permanent applications. This tape is approved for use in convention halls and is widely used because the adhesive will remove cleanly from most surfaces.

Double Sided Transfer Tapes – provides a quick stick and strong holding power, but with no support. Can-Do’s double sided transfer tapes have a release liner designed for ease of application. The acrylic adhesive film is stabilized, even though the adhesive has no carrier. Transfer tapes exhibit very high quick stick and holding power, even at elevated temperatures. Adhesive transfer tapes are used for mounting, splicing, and for closure.

Double Sided Cloth Tapes – are used for carpet installation applications, providing a strong bond to flooring. Can-Do’s double sided cloth tapes have a strong cotton cloth carrier, but they accommodate irregular surfaces. Their rubber adhesive bonds immediately and maintains the integrity of the bond. Double sided cloth tapes are recommended for indoor carpet installation and carpeted stairways and for various industrial mounting applications. Double Sided Polyethylene Foam Tapes – are recommended for general purpose mounting applications. Can-Do’s double sided polyethylene foam tapes have a high performance rubber based adhesive. Can-Do stocks standard foam thicknesses of 1/32″, 1/16″, and 1/8″. Acrylic adhesive systems are also available. These foam tapes are recommended for mounting mirrors, soap dispensers, hooks, and similar applications. These tapes also provide sound dampening. These products are die-cuttable to customer specification.

Double Sided Urethane Double Sided Urethane Foam Tapes are typically polyether and polyester foam tapes that are open cell products and that have low density. They are relatively inexpensive and provide good insulation against dust, light, and sound. These foams typically have a supported adhesive on one side. These products are die-cuttable to customer specification.

Double Sided Paper Tapes – may be used for splicing or laminating where the paper carrier provides additional stability. Can-Do’s double sided paper tapes have a 3.5 mil crepe paper carrier with a high tack rubber based adhesive. This product, with the paper carrier, provides more stability than adhesive transfer tapes. These tapes are recommended for splicing, laminating, and holding items in place.

Double Sided Polyester Tapes – are used when additional strength is required, beyond the adhesive system. Can-Do stocks double sided polyester tapes with both rubber based and acrylic adhesive systems. The polyester carrier for the stocked material is 1 mil, and it is coated with 1.25 mil of adhesive on each side. It is recommended for bonding to a variety of products and for laminating to a variety of materials. It provides dimensional stability and has die cut capabilities.

Double Sided Tissue Tapes – are a lightweight product used for certain laminating and mounting applications. Can-Do’s double sided tissue tapes are lightweight tissues coated with a rubber based adhesive. Similar to double sided paper products, double sided tissue provides conformability and more stability than adhesive transfer tapes. Double sided tissue is recommended for mounting light objects and may be used to laminate cork, paper, plastic, and textiles.

Double Sided Vinyl Tapes – are used in laminating and splicing and also for securing objects. Can-Do’s double sided vinyl tape has a 2 mil PVC carrier and a high tack rubber based adhesive that bonds to a wide variety of substrates. It is used to secure carpet and tiles and is recommended for laminating to many products.

Download our free Guide to Better Bonding

Download Now

Download our free Guide to Better Bonding

Download Now

Download our free Guide to Solving Design Issues with Adhesive Tape

Download Now

Download our free Guide to Solving Design Issues with Adhesive Tape

Download Now