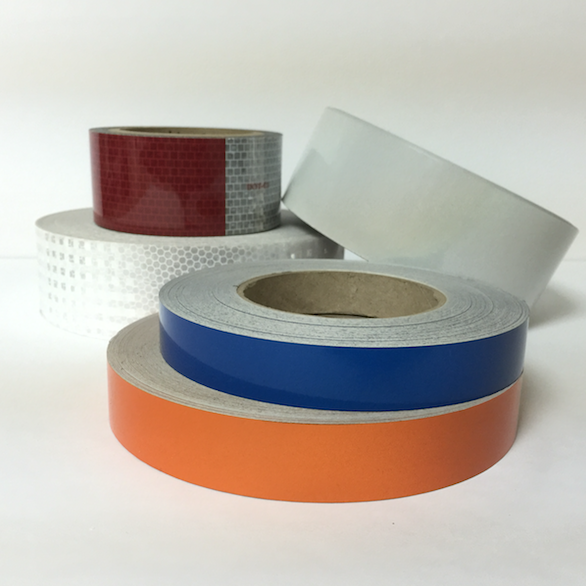

Safety Tapes

Safety tapes and reflective tapes are highly visible in order to warn personnel of hazards or construction conditions. Safety tapes are used for industrial identification, color coding, aisle marking, bundling, flagging applications or to mark an area’s perimeter.

Reflective tapes are used in rotating or moving equipment to provide clear markings that are visible to others. Some options rely on light reflection to show up in the dark, while others work as markers to warn others of potential danger. There are many different widths, colors and reflective styles available, ensuring there is an option for most situations. The correct safety tape and its application is critical to operations of any business. It protects, lowers costs, satisfies requirements, and pleases regulators.

-

Barricade Tapes (2)

-

Hazard Stripe Tapes (3)

-

Marking Tapes (1)

-

Non-Skid Tapes (3)

-

Reflective Tapes (1)

We market 5 distinct varieties of safety tapes:

- Barricade and Detectable Tapes

- Hazard Stripe Tapes

- Non-Skid Tapes

- Reflective Phosphorescent Tapes

- Marking Tapes

Adhesives for Safety Tapes:

There are two choices of adhesives for safety tapes: non-adhesive and single-sided adhesive. Non-adhesive safety tapes and reflective tapes do not have an applied adhesive but may be self-adhering.

PTFE thread sealing tape or Teflon® tape is a type of non-adhesive tape. Teflon is a registered trademark of DuPont Dow Elastomers. With single-sided safety and reflective tapes, only one side of the backing or carrier is coated with adhesive.

Backing Material for Safety Tapes Include:

-

Cloth

-

Metal

-

Paper

-

Plastic

-

Rubber

Thanks to 3M for the above vides of tape application and usage.

Download our free Guide to Better Bonding

Download Now

Download our free Guide to Better Bonding

Download Now

Download our free Guide to Solving Design Issues with Adhesive Tape

Download Now

Download our free Guide to Solving Design Issues with Adhesive Tape

Download Now