Splicing Tapes

Splicing tapes are available in a variety of carriers with different adhesive systems. They may be single or double-coated, have a polyester, film, or paper carrier, have high temperature adhesives, be repulpable, and have other features as well. The necessary characteristics are determined by the material being spliced. Please contact us with your specification needs, and request a quote.

Showing all 3 results

-

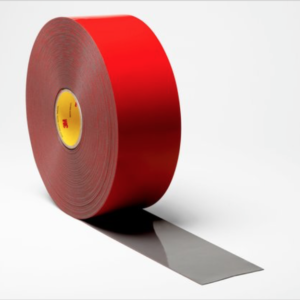

Custom Converted Gray Acrylic Foam Tape

-

Custom Slit to Width x 72 yd. x 3.56 mil Green Splicing Tape

General Information: Splicing tapes are used to make a manufacturing process continual, joining the end of a web of material to the beginning of a new web, or roll of material. This helps avoids valuable down time rethreading the new roll through the machine or press. Can-Do National Tape makes available single and double-coated splicing tape. The adhesive on splicing tapes can be rubber or acrylic.

Technical Details: The web of material that is being spliced and the production process for that material determines the most appropriate splicing tape for the application. Different combinations of tape substrates and adhesive formation ensure optimal performance. The various substrates include different papers and films while the adhesive should be compatible with the material being spliced and the machines or presses being used in the production processes. Splicing tapes are used in a variety of industries and production processes.

Applications: Double-coated splicing tapes are suitable for use with laminators, coaters, and other converting operations. Can-Do National Tape offers double sided splicing tapes suitable for all these applications. They can be used for performing flying splices, manual splices, core starting, and roll finishing applications. These tapes have high-temperature resistance and shear strength. Applications include flexible packing and nonwovens.

In addition, splicing tape is designed for splicing release coated paper and film in elevated temperature or in conditions where initial high tack is required, for photo processing, in label or pressure sensitive coating applications that require a functional splice and for butt splice/overlap splicing applications. Repulpable splicing tapes dissolve in water. These splicing tapes ensure that the substrate and adhesive do not gum up the machinery and stop the production process in the production of paper, where water is used.

Butt splicing requires a single coated splicing tape and is done by laying the two webs, or rolls, side by side. With a single coated splicing tape, two ends are joined together. Overlap or flying splicing is done by applying a double-coated tape to the end of the web or roll. The liner of the tape is then removed to expose the second side of the adhesive and the new web, or roll is overlapped to the adhesive, and ultimately joining the two together.

Can-Do National Tape has experienced and knowledgeable consultants to help determine which splicing tape best suits your needs. We can recommend the right product for you.

Download our free Guide to Better Bonding

Download Now

Download our free Guide to Better Bonding

Download Now

Download our free Guide to Solving Design Issues with Adhesive Tape

Download Now

Download our free Guide to Solving Design Issues with Adhesive Tape

Download Now