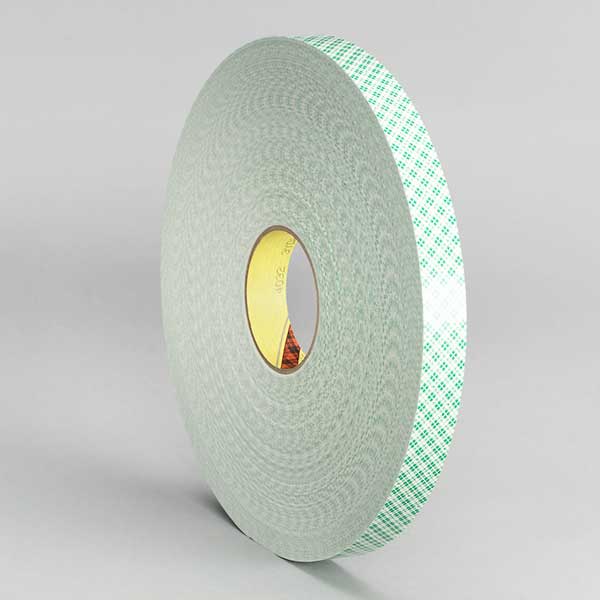

Foam Tapes

Can-Do offers a comprehensive selection of foam tapes to meet the diverse needs of a wide range of applications. Foam tapes are well suited for sound dampening, insulating, gasketing, cushioning/padding, and sealing and are designed to enhance the appearance and improve the overall performance of your product design.

Showing all 9 results

Need Help Choosing The Right Adhesive? Not Sure How To Prep The Surface?

Download our free Guide to Better Bonding

Download Now

Download our free Guide to Better Bonding

Download Now

Need Assistance with Troubling Design Issues? See What Tape Can Do!

Download our free Guide to Solving Design Issues with Adhesive Tape

Download Now

Download our free Guide to Solving Design Issues with Adhesive Tape

Download Now