- Overview

- Applications

- Technical Data

- Warranty

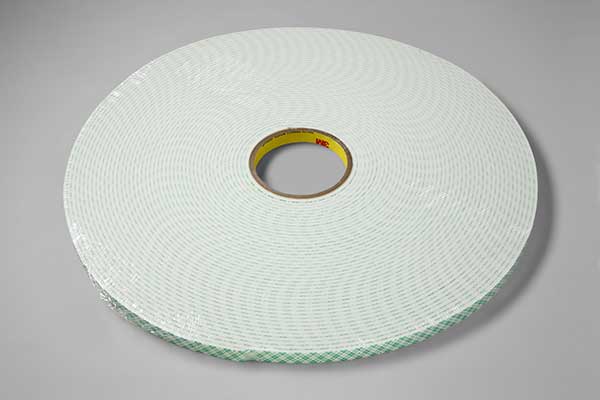

3″ x 18 yd. x 250 mil Beige Double-Coated Urethane Foam Tape

3M Double-Coated Urethane Foam Tape 4004 is a thick, double-coated, open-cell urethane foam tape with a paper liner. 3M Double-Coated Urethane Foam Tapes are a family of tapes that are conformable foams offering high shear strength and are available with either a high temperature holding acrylic adhesive system or a rubber adhesive system for bonding to various types of surfaces for mounting, joining and holding.

- High shear strength

- Durable on interior mounting applications

- Clean appearance

Custom Sizes Available

For custom sizes, please call 800-643-5996 or Request a Quote.

Request Quote Request A Sample

Working On A Prototype?

Have a sketch or drawing but you're not sure where to go next?

Our professional staff will provide guidance on the best materials and process to turn your idea into a profitable venture.

Applications

INDUSTRIES: IndustrialAPPLICATION: Bonding

APPLICATION DESCRIPTION:

Bonds and fills gaps, including irregular surfaces. Provides handling convenience and cushioning.

APPLICATION NOTES:

Bond strength is dependent upon the amount of adhesive-to-surface contact developed. Firm application pressure helps develop better adhesive contact and improve bond strength.Technical Data

BRAND: 3MMATERIAL DESCRIPTION:

| SIZE: | 3" x 18 yd. |

| COLOR: | Beige |

| ADHESIVE TYPE: | Pressure-Sensitive |

| CONSTRUCTION: | Double Sided |

| LINER: | Green Plaid |

TECHNICAL DATA:

| ADHESIVE LAYER: | Acrylic |

| ADHESIVE LAYER DESCRIPTION: | 3M 100 firm acrylic |

| BACKING/CARRIER MATERIAL: | Foam |

| THICKNESS: | 250 mil (6.4 mm) Nominal |

| TENSILE STRENGTH: | 90 (620) psi (kPa) |

| ELONGATION: | 90% |

DATA SHEET:

3″ x 18 yd. x 250 mil Beige Double-Coated Urethane Foam Tape (PDF)

SHELF LIFE:

To obtain best performance, use these products within 24 months from date ofmanufacture except 3M„¢ Double Coated Urethane Foam Tape 4085 which is18 months from date of manufacture. Store in original cartons at 70°F (21°C) and 50% relative humidity.NOTES:

Physical and performance characteristics shown are obtained from tests recommended by vendor. Quality Assurance and Technical Service Departments do not represent a guarantee of product performance. Individual rolls may vary slightly from these averages. The user should determine whether the product is fit for a particular purpose and is suitable for the user's method of application before use.

The information listed above has been obtained from controlled laboratory tests and is reliable, but should not be used for the purpose of writing specifications. It is offered in good faith, but without guarantee, as conditions and methods of use of our products are beyond our control. It is recommended that the prospective user determine the product suitability before adapting for commercial use.

Warranty

Physical and performance characteristics shown are obtained from tests recommended by vendor. Quality Assurance and Technical Service Departments do not represent a guarantee of product performance. Individual rolls may vary slightly from these averages. The user should determine whether the product is fit for a particular purpose and is suitable for the user's method of application before use.

The information listed above has been obtained from controlled laboratory tests and is reliable, but should not be used for the purpose of writing specifications. It is offered in good faith, but without guarantee, as conditions and methods of use of our products are beyond our control. It is recommended that the prospective user determine the product suitability before adapting for commercial use.