There are three primary ways to manage structural vibration and the noise that it creates:Of the sources of noise in the operation of equipment, it’s important to distinguish between structural noise and airborne noise. Structural noise results from mechanical vibration energy emitted by a product that travels throughout the structure as well as materials with which it comes in contact. Airborne noise is produced by the interaction of a vibrating surface with the surrounding air.

- Introduce a low friction surface between parts of a product that come in contact with each other.

- Change the vibration mode of the structure by adding a vibration dissipating damping material.

- Isolate the vibration from traveling from one part of the product to another, or to an adjacent structure

Airborne buzz, squeak, and rattle can be reduced by adding absorbers, barriers, and layers to absorb or reflect sound energy.

3M offers a wide range of solutions for managing the vibration issues that cause both structural and airborne noise.

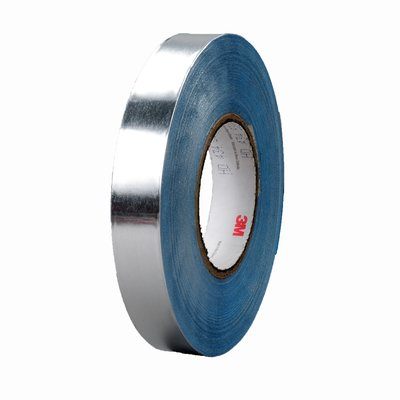

Vibration Damping Tape

These tapes are applied to parts of a device that are prone to vibration. Made using a soft adhesive polymeric damping material and a thick aluminum foil, these tapes manage vibration through constrained layer damping. When the vibration occurs, the vibration energy is converted to heat.

VHB™ Tape

Slick Surface Tapes

Developed using low friction films, UHMWPE and PTFE, the films are coated with an adhesive for easy application in places between vibration generating moving parts.

3M offers a variety of laminating adhesives, which can be used with a broad range of foam and cushioning materials to provide solutions that prevent noise emission from product surfaces.

Bumpon™ Protective Products

Rubber pads used to isolate parts, preventing the transmission of vibration; lined with an adhesive for easy attachment.

Thinsulate™ Acoustic Insulation

The unique fiber structure absorbs airborne noise energy; suitable for a variety of products.

E-A-R™ Business

Sound barrier materials that can be used to reflect air-borne noise.

Can-Do Tape is your source for adhesive tape materials to manage vibrating noise. Contact us to discuss your project!