- How to get a strong bond with Pressure Sensitive Adhesive

- A Guide to High and Low Surface Energy Materials

How to get a strong bond with Pressure Sensitive Adhesive

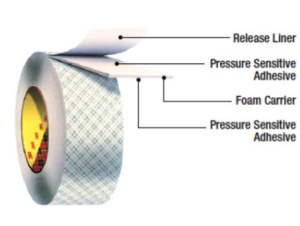

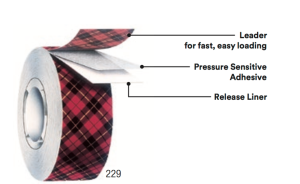

To get an advanced adhesive tape bond, you need to do what the name implies. Pressure sensitive adhesive (PSA) requires a specific amount of pressure when applied to reach the desired bond to the substrate. To accomplish adhesive tape bonding, the surfaces should be clean and dry. Most adhesives form their optimum bond within 72 hours after being applied. During this time, the adhesive is allowed to wet-out on the substrate. Some materials are harder to bond to than others. Low surface energy materials do not allow the adhesive to flow or wet-out, while high surface energy materials do.

A Guide to High and Low Surface Energy Materials

| High Surface Energy Materials | Low Surface Energy Materials | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

Note: These Values are provided only as a guide.

<< Adhesives Used For Tape >> << Adhesive Tape Consultant >>