- What is Heat Activated Tape?

- What are the Advantages of Heat Activated Tape?

- Heat Activated Foam and It’s Possibilities

What is Heat Activated Tape?

Heat activated tape is usually tack-free until it is activated by a heat source, and is not considered to be a pressure sensitive tape. The industrial bonding and welding of hot-melt adhesives in film form, thermoplastic adhesive films have established a strong position in the last 30 years. Thermoplastics may be reshaped by heating and are typically used to produce or bond parts together by various polymer processing techniques.

Thermoplastic adhesive films permit continuous or batch bonding even on large surface areas with a high degree of automation and high production speeds. Materials, from textiles or non-woven to aluminum foil, from PVC to PU foam, can be bonded in calendars, presses or other installations by means of heat, pressure and time.

Composites and Textile Industries are among the most appropriate targets for adhesives films since they do not require conditioning lines in the processing plants. It is sometimes used in packaging, for example, a tear strip tape for cigarette packs. This is particularly useful in the semiconductor industry.

Heat-activated (hot melt) adhesive systems require a defined period of time at elevated temperatures (normally 180˚F or higher) to achieve final bonding strength. Temperature, pressure and dwell time are used to effect a final cure and bond. Hot Melt Tapes have very strong holding power and wins when it comes to adhesion strength. It is very flexible and has significantly higher adhesion as compared to acrylic tape on most surfaces including fiberboard.

Heat Seal adhesives consist of a heat activated thermoplastic film formulated from Polyurethane, Nylon, Polyester, or Vinyl and adheres to virtually any substrate. Heat seal thermoplastic film tapes offer a wide range of possibilities when it comes to laminating, molding, and welding.

Heat activated adhesives are custom formulated for use on paper, textiles, and metal foil. Although usually supplied in its neutral color, this product can be tinted to achieve various colors for coding purposes. Heat activated adhesives are generally applied to a substrate via roll coat operation. The coated material is in a non-tacky state until heat is applied, which activates the bonding property.

When heat and pressure are applied, the tape is activated, and ultimately provides an extremely high bond. The heat activation point is entirely dependent on the substrate sensitivity and scorch point.

What are the Advantages of Heat Activated Tape?

- Can be designed for rigid or flexible applications.

- Excellent adhesion.

- Re-positional

- Adheres to a wide variety of materials.

- Excellent for induction curing and seal.

- Washing machine durable.

- EPDM extrusion profile bonding for the automotive industry.

- Electrical appliance industry.

- Provides excellent performance bonding strength to most rubber, EPDM, PU and PVC based plastic materials.

Heat Activated Foam and It’s Possibilities

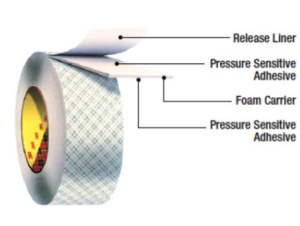

Acrylic foam tapes with a heat-activated adhesive on one side is used to bond to weatherstrip seals, gaskets and other elastomeric materials for automotive and industrial applications.

For bonding polypropylene, polyethylene, polyester, nylon, paper, ceramics, wood, fibers & other materials. Capabilities of adhesives include the ability to function in temperatures ranging from 40 degrees C to 140 degrees C or from -30 degrees C to 100 degrees C. Adhesives are available in various grades including inflammable & web grade.

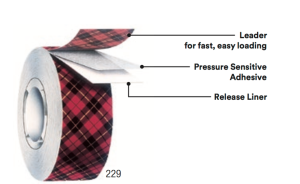

Permanent, solvent acrylic adhesive designed for use with heated. The initial tack is either none or very low, allowing most prints to be repositioned before heat activation. This feature makes it a popular choice for mounting delicate prints and/or displays. Once heat-activated, the bond is strong enough to mount to rigid substrates. Selecting the right heat-activated adhesive is more an engineering specification.

The Heat-activated adhesive coating allows for an aggressive bonding to hard-to-bond surfaces such as rubber, EPDM, PU and PVC-based plastic materials. And can be made of different carriers; foam, film, and tissue suitable for different types of applications.

<< PSA Tape >> << Water Activated Tape >>